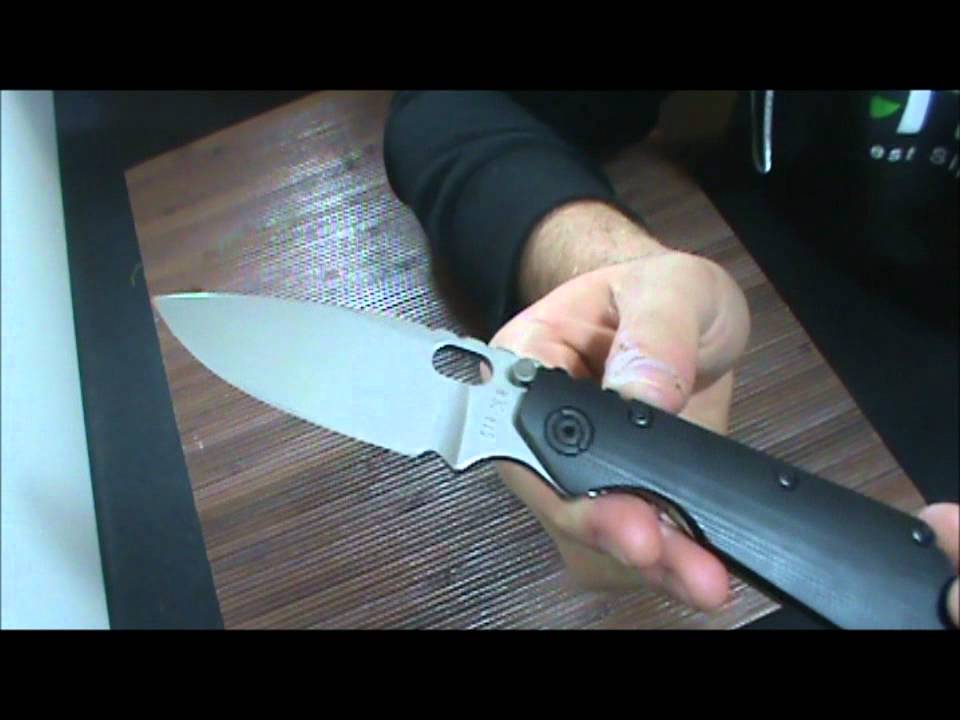

Monkey Edge Strider SMF 3V

CPM 3V is a high toughness, wear-resistant tool steel made by the Crucible Particle Metallurgy process. It is designed to provide maximum resistance to breakage and chipping in a high wear-resistance steel. It offers impact resistance greater than A2, D2, Cru-Wear, or CPM M4, approaching the levels provided by S7 and other shock resistant grades. CPM 3V is intended to be used at 58/60 HRC in applications where chronic breakage and chipping are encountered in other tool steels, but where the wear properties of a high alloy steel are required.

The wear and toughness properties of CPM 3V make it an excellent alternative to shock-resistant steels such as S7 or A9, where they typically wear out too quickly, but where grades such as A2, CruWear, or CPM M4 tend to fail by breaking or chipping. CPM 3V offers the highest impact toughness of any tool steel with this range of wear resistance.

Mechanical Properties:

Impact Toughness

CPM 3V offers impact toughness (Charpy C notch) approaching the shock-resistant tool steels, with much greater wear resistance.

Wear Resistance

CPM 3V offers substantial improvements in tool wear life when compared with conventional tool steels such as A2 and D2. CPM 3V's high vanadium content offers wear resistance similar to M2 high speed steel.