Are Striders Worth The Money? (Final Video....I Think)

Even more thoughts on the subject. I know I have already spoke about this at length, but I don't feel that I have fully said everything I want on this subject. Hopefully this will be the last "are they worth the money" videos I do, but you never know. My thoughts, feelings, and knowlege base is ever changing there for my opinions follow along.

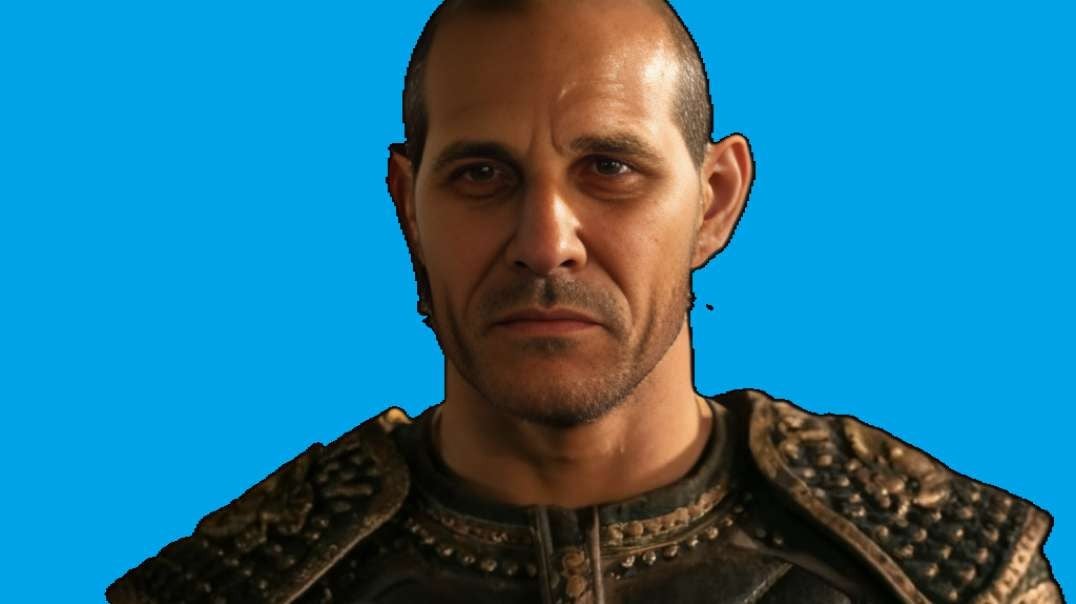

Strider Knives, Inc. is a custom and production knifemaking facility headed by Mick Strider and Duane Dwyer based in San Marcos, California.

Strider Knives makes folding knives and fixed-blade knives, using metals such as ATS-34, CPM S30V steel, titanium, stellite, beryllium, damascus steel, and BG-42 for the blades.

Strider fixed blade knives utilize either parachute cord or G-10 fiberglass for the handle material.

Strider uses a proprietary heat treatment originally developed by Paul Bos of Buck Knives. This resulted in knives with blades of ATS-34 or BG-42 coming back from heat treat with a very dark colored blade which would then be bead blasted a flat grey color. After masking a blade before beadblasting, Mick Strider found it resulted in a striping or camouflage effect and it has become a part of the design. As the newest steel Strider uses, CPM S30V does not darken after heat treating, a black oxide coating is applied beforehand.

After eight years of making fixed blade knives, Strider turned to making folding knives. Strider's goal was to produce a folding knife that was as strong as a fixed blade. To work toward this goal, Strider relied on the use of G10 Fiberglass handles, titanium liners thicker than what was in current use throughout the cutlery industry and an oversized pivot screw 0.19" in diameter. The end results were two linerlocks known as the AR and GB models. Strider makes titanium handled framelock folding knives. These models utilize the handle itself as the locking mechanism and are named the SMF, SnG, PT, and RC models.

Strider's first project as a company was to supply Naval Special Warfare Group 1 with WB and BG models in 1994. Strider Knives currently makes several models specifically for units of the US Military in the Global War on Terror, each with its own NSN. National Stock Numbers are: Strider SMF (officially - Knife, Folding, Special Mission) 1095-01-531-5015, Strider DB-L (officially - Knife, Fixed, Camo) 1095-01-531-5023, the JB1 (officially - Shroud Knife) 1670-09-000-3920, and the Probe Knife 1095-01-503-7231, built for landmine detection.

Strider Knives has designed a new bayonet it hopes to market to the US military. The blade is CPM S30V and it features a tang extending all the way to the latch plate for increased strength. Strider designed the bayonet for Zero Tolerance Knives, which will release it as the ZT Bayonet D9.

Strider Knives has manufactured modern versions of classic military designs such as the V-42 Stiletto, the Marine Raider Stiletto, the SOG Knife, the USMC Fighting Utility Knife, and the Fairbairn-Sykes Fighting Knife. These versions have the same profile as the originals, but incorporate modern steel and materials in their designs. The SOG Knife, Marine Raider Stiletto, and V-42 Stiletto have been used to raise funds for Veteran's Groups associated with those units.

![The Golden Conversation 77: Do You Think The Judge Is Going To Feel Sorry For The Convicted Felon? [Police Called]](https://video.ugetube.com/upload/photos/2024/11/nzOwgrSgH9c3hMjO5N7d_14_1f58861b70f0f30a7e6b4f8787b49329_image.png)